Fasteners and Machining: Incorporating Precision and Stamina in Production

Navigating the Globe of Fasteners and Machining: Techniques for Accuracy and Speed

In the elaborate realm of fasteners and machining, the mission for precision and speed is a perpetual challenge that demands precise interest to detail and calculated preparation. From comprehending the varied variety of bolt types to choosing ideal materials that can stand up to extensive demands, each step in the process plays a critical role in accomplishing the preferred outcome.

Understanding Fastener Types

When selecting bolts for a task, recognizing the numerous kinds readily available is critical for guaranteeing ideal performance and reliability. Fasteners come in a wide variety of types, each designed for specific applications and requirements. Bolts are made use of with nuts to hold materials together, while screws are versatile fasteners that can be used with or without a nut, depending on the application. Nuts, on the other hand, are internally threaded fasteners that mate with bolts or screws, providing a protected hold. Washers are essential for dispersing the lots of the fastener and protecting against damage to the material being attached. Additionally, rivets are long-term bolts that are ideal for applications where disassembly is not required. Comprehending the differences between these fastener types is important for choosing the right one for the task, ensuring that the connection is strong, durable, and trusted. By picking the ideal fastener kind, you can optimize the efficiency and durability of your project - Fasteners and Machining.

Picking the Right Products

Recognizing the relevance of selecting the right products is extremely important in ensuring the optimal performance and dependability of the chosen fastener types reviewed formerly. When it comes to bolts and machining applications, the material option plays a vital function in establishing the total toughness, longevity, deterioration resistance, and compatibility with the designated environment. Different materials offer varying residential or commercial properties that can dramatically impact the efficiency of the fasteners.

Usual materials utilized for fasteners consist of steel, stainless-steel, titanium, aluminum, and brass, each having its distinct strengths and weak points. Steel is renowned for its high toughness and resilience, making it appropriate for a wide variety of applications. Stainless steel supplies outstanding rust resistance, perfect for atmospheres susceptible to moisture and chemicals. Aluminum is light-weight and corrosion-resistant, making it appropriate for applications where weight decrease is vital. Brass is commonly selected for its visual appeal and superb conductivity. Titanium is known for its exceptional strength-to-weight ratio, making it excellent for high-performance applications. Picking the appropriate material includes considering elements such as stamina needs, ecological problems, and budget restraints to ensure the wanted performance and long life of the fasteners.

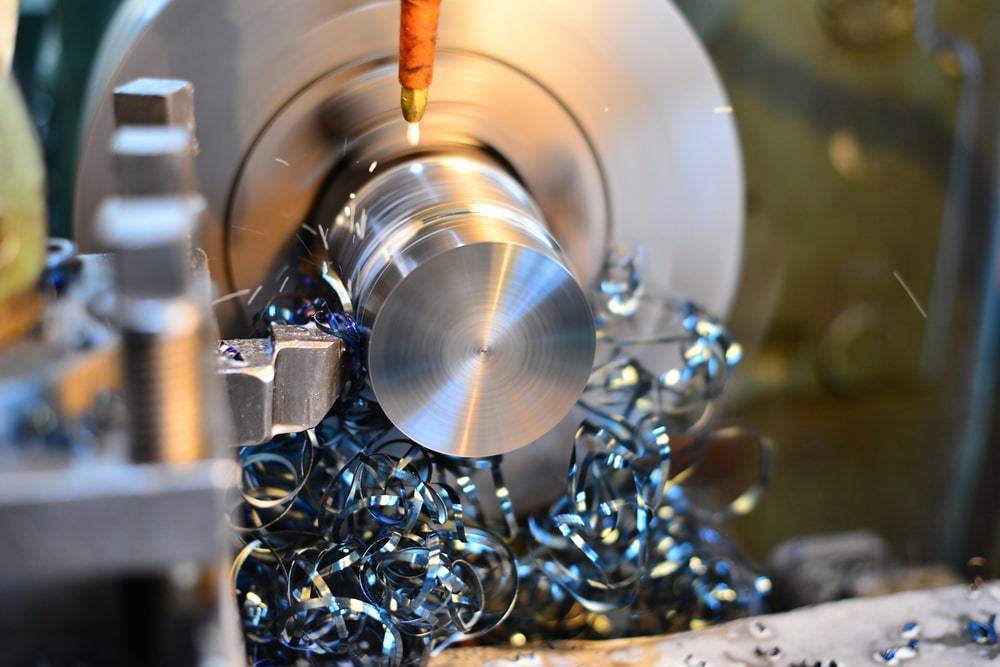

Accuracy Machining Techniques

Along with CNC machining, various other accuracy methods like grinding, transforming, milling, and drilling play essential functions in fastener production. Grinding aids achieve great surface area finishes and limited dimensional tolerances, while transforming is typically made use of to produce round components with accurate sizes. Milling and drilling operations are crucial for shaping and developing holes in fasteners, guaranteeing they fulfill exact specs and feature appropriately.

Enhancing Speed and Effectiveness

To optimize bolt manufacturing procedures, it is crucial to enhance procedures and navigate to this website carry out reliable methods that complement precision machining strategies. Automated systems can manage recurring jobs with precision and rate, allowing employees to concentrate on even more complex and value-added tasks. By integrating these strategies, suppliers can achieve a balance in between speed and precision, ultimately boosting their affordable edge in the fastener sector.

Quality Control Procedures

Carrying out rigorous quality assurance measures is critical in making sure the reliability and uniformity of fastener items in the production procedure. Quality control actions include numerous stages, beginning with the selection of resources to the last assessment of the finished bolts. One fundamental aspect of high quality control is carrying out thorough product evaluations to validate compliance with requirements. This entails examining variables such as material toughness, make-up, and stamina to assure that the fasteners satisfy market requirements. Furthermore, monitoring the machining refines is essential to copyright dimensional precision and surface area coating high quality. Using advanced technology, such as automated inspection systems and accuracy measuring devices, can improve the accuracy and efficiency of quality control treatments.

Routine calibration of equipment and equipment is essential to maintain consistency in production and make certain that fasteners meet the required resistances. Implementing rigorous procedures for identifying and dealing with problems or non-conformities is vital in stopping substandard items from entering the market. By establishing a thorough quality assurance framework, suppliers can copyright the credibility of their useful content brand name and deliver fasteners that satisfy the greatest criteria of performance and toughness.

Conclusion

In the detailed world of fasteners and machining, the quest for accuracy and speed is a perpetual obstacle that requires thorough focus to information and critical preparation. When it comes to bolts and machining applications, the product option plays an essential function in determining the overall strength, resilience, corrosion resistance, and compatibility with the intended environment. Precision machining involves numerous innovative approaches that make sure the tight tolerances and specifications required for bolts.In enhancement to CNC machining, other precision techniques like grinding, turning, milling, and drilling play essential duties in bolt production.To optimize bolt manufacturing procedures, it is crucial to enhance operations and execute efficient approaches that enhance accuracy machining methods.